- Cflow

- Production Schedule Approval Automation

Production Schedule Approval Automation

Clow Team

Production schedule approvals are at the core of manufacturing efficiency, resource planning, and on-time delivery. When handled manually, production scheduling often results in capacity conflicts, missed deadlines, inventory issues, and costly rework. Recent industry research shows that 58% of manufacturers struggle with schedule coordination due to fragmented approval processes.

Without automation, operations, production planners, procurement, and leadership struggle to coordinate production timelines, inventory availability, machine capacity, and supplier deliveries. This guide walks you through exactly how Cflow automates Production Schedule Approval Process, from planning submission to production start.

What Is Production Schedule Approval Process?

The Production Schedule Approval Process governs how production planners submit proposed schedules, coordinate cross-functional reviews, and obtain approvals to commit resources for manufacturing runs. It ensures capacity alignment, inventory sufficiency, labor availability, and customer delivery targets are met.

Think of production schedules like tightly synchronized commitments, every proposed run must be reviewed across multiple teams to ensure flawless execution.

Recent industry research shows that automating production scheduling improves on-time production rates by 50% and reduces rescheduling conflicts by 60%.

Why Production Scheduling Is Important for Operations Teams

Capacity Utilization

Customer Commitments

Cross-Functional Coordination

Audit Readiness

Key Benefits of Automating Production Schedule Process with Cflow

- Centralized Schedule Submission Portal : Cflow provides one place where production planners submit schedules, and operations, procurement, quality, and leadership collaborate to review and finalize schedules, fully eliminating disconnected spreadsheets.

- Dynamic Routing Based on Production Type : Cflow applies conditional logic based on product line, plant location, customer priority, or order size to route schedules to the appropriate teams.

- Multi-Level Cross-Functional Approvals : Schedules automatically route through production managers, inventory controllers, procurement teams, quality leaders, logistics managers, and executives depending on production scale, raw material availability, or customer priority.

- Real-Time Notifications & Escalations : Cflow notifies stakeholders as schedules move through each review stage and applies escalation rules to prevent bottlenecks that could delay production start.

- Inventory & Procurement Synchronization : Cflow validates raw material availability, triggers procurement alerts if materials are short, and ensures that procurement aligns with scheduled production start dates.

- Full Change Log & Revision History : All schedule changes, capacity adjustments, and approvals are timestamped and archived for audit readiness and continuous improvement analysis.

- Mobile Accessibility : Production planners, plant managers, and executives can review and approve production schedules directly from mobile devices, ensuring faster coordination while on-site or remote.

User Roles & Permissions

Production Planner (Initiator)

- Responsibilities: Submit production schedule with proposed start dates, batch sizes, and resource plans.

- Cflow Permission Level: Submit Form.

- Mapping: “Production Planners” group.

Production Manager

- Responsibilities: Validate resource availability, machine capacity, and labor shifts.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Production Managers” group.

Inventory Controller

- Responsibilities: Validate raw material inventory and trigger replenishment if needed.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Inventory Team” group.

Procurement Officer

- Responsibilities: Review pending material requirements and vendor lead times.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Procurement Team” group.

Quality Manager (Conditional)

- Responsibilities: Approve schedules for quality inspections and certification timelines.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Quality Team” group.

Logistics Manager (Conditional)

- Responsibilities: Validate outbound shipping capacity post-production.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Logistics Team” group.

Executive Leadership (Conditional)

- Responsibilities: Final approval for high-volume or strategic production schedules.

- Cflow Permission Level: Approve/Reject.

- Mapping: “Executive Team” group.

Compliance Auditor

- Responsibilities: Review archived schedule changes.

- Cflow Permission Level: View Only.

- Mapping: “Compliance” group.

Form Design & Field Definitions

Field Label: Schedule Request ID

- Type: Autonumber

- Auto-Populate: Generated on submission.

Field Label: Product Line

- Type: Dropdown (Product A, B, C, etc.)

- Logic/Rules: Drives routing.

Field Label: Production Site

- Type: Dropdown

- Auto-Populate: From planner profile.

Field Label: Proposed Start Date

- Type: Date Picker

- Logic/Rules: Mandatory.

Field Label: Planned Output Quantity

- Type: Numeric Field

- Logic/Rules: Mandatory.

Field Label: Resource Requirements Summary

- Type: Text Area

- Logic/Rules: Mandatory.

Field Label: Material Availability Check

- Type: Checkbox

- Logic/Rules: Inventory must validate.

Field Label: Procurement Status

- Type: Text Area

- Logic/Rules: Procurement officer completes.

Field Label: Quality Review Notes

- Type: Text Area

- Logic/Rules: Required if quality review triggered.

Field Label: Logistics Readiness Status

- Type: Text Area

- Logic/Rules: Required for logistics coordination.

Field Label: Executive Comments

- Type: Text Area

- Logic/Rules: Required for executive approvals.

Field Label: Final Schedule Approval Confirmation

- Type: Checkbox

- Logic/Rules: Marked by production manager when fully approved.

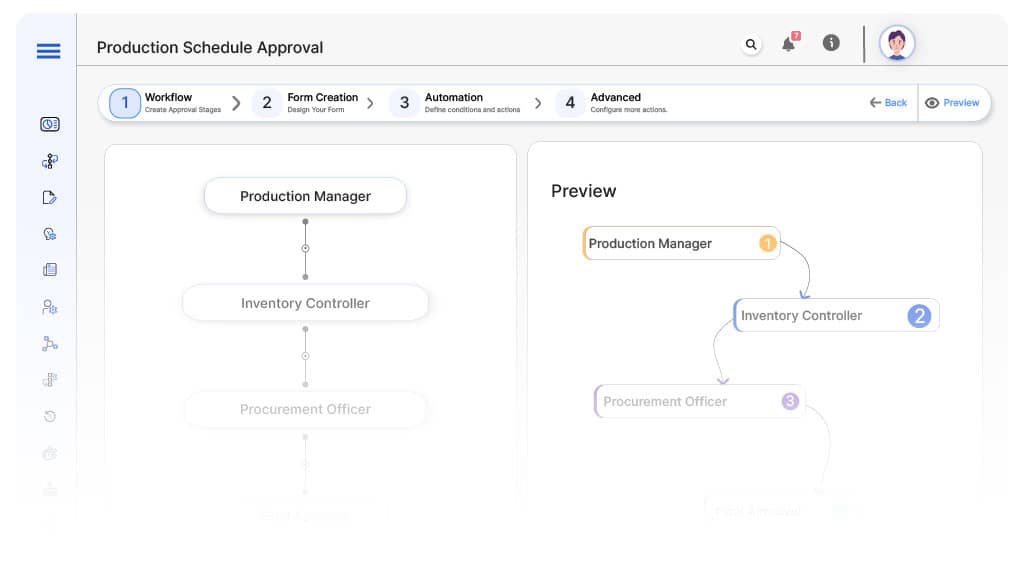

Approval Flow & Routing Logic

Submission → Production Manager

- Status Name: Pending Production Review

- Notification Template: “Hi Production Manager, schedule request submitted for review.”

- On Approve: Moves to Inventory.

- On Reject: Returns to Planner.

- Escalation: Reminder after 1 day.

Production → Inventory Controller

- Status Name: Pending Inventory Review

- Notification Template: “Hi Inventory, material availability check required for production schedule.”

- On Approve: Moves to Procurement.

- On Reject: Returns to Production.

- Escalation: Reminder after 1 day.

Inventory → Procurement Officer

- Status Name: Pending Procurement Review

- Notification Template: “Hi Procurement, verify material orders align with schedule.”

- On Approve: Moves to Quality (if applicable).

- On Reject: Returns to Inventory.

- Escalation: Reminder after 1 day.

Procurement → Quality Manager (Conditional)

- Status Name: Pending Quality Review

- Notification Template: “Hi Quality, upcoming production run requires inspection alignment.”

- On Approve: Moves to Logistics (if applicable).

- On Reject: Returns to Procurement.

- Escalation: Reminder after 1 day.

Quality → Logistics Manager (Conditional)

- Status Name: Pending Logistics Review

- Notification Template: “Hi Logistics, confirm shipping slots post-production run.”

- On Approve: Moves to Executive Leadership (if applicable).

- On Reject: Returns to Quality.

- Escalation: Reminder after 1 day.

Logistics → Executive Leadership (Conditional)

- Status Name: Pending Executive Approval

- Notification Template: “Hi Leadership, major production schedule requires final sign-off.”

- On Approve: Moves to Schedule Locked.

- On Reject: Returns to Logistics.

- Escalation: Reminder after 1 day.

Final → Schedule Locked

- Status Name: Production Schedule Approved

- Notification Template: “Production schedule locked and ready for execution.”

Implementation Steps in Cflow

Create a new workflow

Design the form

Set up User Roles/Groups

Build the process flow diagram

Configure notifications

Apply templates and escalation rules per Approval Flow.

Set conditional logic

Save and publish workflow

Activate process.

Test with a sample request

Adjust logic if needed

Go live

Example Journey: Large Q3 Batch Run

FAQ's

Setup typically completes within 5–7 business days.